1.1. What supplies you will need in work?

1.4. Is it possible to increase the size of the working field of the machine?

1.5. Can I burn thick pieces of wood?

1.6. What is the size of the machine?

1.7. What is the capacity of the machine?

2.1. When the machine is running is it a strong smell allocated?

2.2. On what surface can I burn the image?

2.3. What else do I need for wood burning?

2.4. Whether has value how to install the workpiece on the machine?

1. Technical questions

1.1. What supplies you will need in work?

A removable element is a nichrome wire for making searing tip. Also, the shafts should be lubricated with household oil for sewing machines.

1.2. What stock nichrome filament goes along with the machine? Where it can be purchased in the future?

Supply nichrome wire is included with the machine, which is enough for about 120-150 portraits (when the rate of change tip every 7 portraits). Such a reserve of approximately lasts for six months. An additional supply can be purchased from us or you can search it in the radio parts stores. You can order a supply of wire made of alloy nichrome-tungsten (made in Germany) for $ 5. It is enough for another 500-700 portraits. We can send wire together with the machine or a separate parcel through the post.

1.3. How to replace the tip?

Straighten 6 cm of nichrome wire and bend it in the shape of tip, which is in stock. Unscrew the terminals on the floating head CNC and replace the old tip with the new. Tight tighten. The whole process takes about 3-5 minutes.

1.4. Is it possible to increase the size of the working field of the machine?

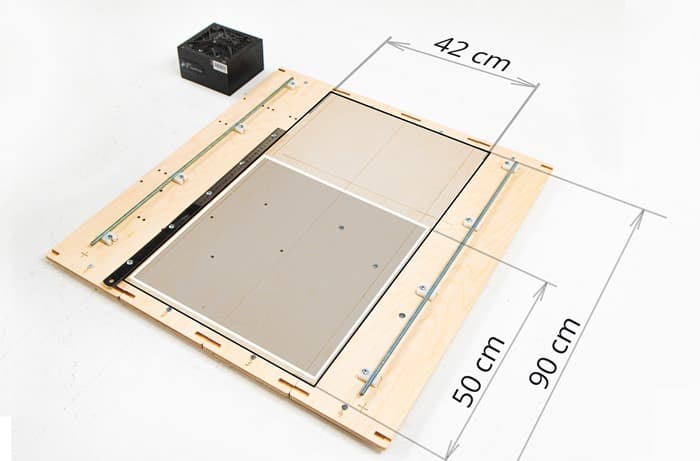

Yes, it is possible to make the size of the working field of 90*42 cm (16.5 in*35 inches). To increase the size of the working field you need to change 2 rods (studs) on the 1 meter rods with metric thread with a diameter of 8 mm. The cost of stud is about few dollars. You can buy them at hardware stores or fastener stores. We can’t put them in the machine when sending because they don’t fit in a shipping box. If we send the studs (rods) with the second place, there were cases that the rods were bent during the transportation process, leading them into disrepair. Moreover, for larger size there is a rise in the cost of shipping.

You will need to replace two rods (it is standard thing you can find in the hardware/construction store):

1.5. Can I burn thick pieces of wood?

The standard thickness of plywood or wood, which the machine burns is from 1 to 10 mm. Thus, it is possible to increase the thickness of the workpiece to almost any thickness, raising the entire structure of the machine. It is necessary to enclose the slats or bars for fastening and fasten them on the table to prevent displacement of the machine.

1.6. What is the size of the machine?

The machine comes in a box that converts to a table size of 75*75 cm (2,5*2,5 ft).

1.7. What is the capacity of the machine?

90 watts, which is comparable to the consumption of the computer.

2. Work with the machine

2.1. When the machine is running is it a strong smell allocated?

If you use a clean plywood (not moisture proof), the smell is not significant. Many of those who first become acquainted with the machine notices that the smell is significantly weaker than the manual weightily. The machine it is possible to put the house and ventilate the room after burning.

2.2. On what surface can I burn the image?

We usually use birch plywood because it has bright surface with a small amount of resin on the surface. The grade of plywood is not worse than the CP-CP (grade 2/2 or 2/4).

It is also possible to burn out on light leather.

You cannot use plywood, impregnated with any of the compositions. For example, moisture resistant plywood, laminates, lacquered or laminated wood.

2.3. What else do I need for wood burning?

You can purchase an electric jig saw for fast cutting of plywood. Also buy sandpaper with a 100-120 grain for leveling the surface. If you have a lot of orders you can buy a sander with a round disk to simplify the sanding.

2.4. Whether has value how to install the workpiece on the machine?

Yes, you must burn on a direction of grain of wood. So the line of burning superimposed on the line of the grain of wood. If You burn across the grain, then the image will appear fine mesh.